Food Processing

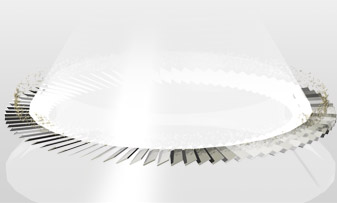

The TORBED process has shown itself to have unique capabilities in this application in producing higher quality, lighter and more consistent product with lower energy consumption. Indeed, some shapes of product can only be air expanded in a TORBED reactor. High heat and mass transfer and precision of control with the TORBED reactors have provided these advantages. The installation is quiet and compact.

The TORBED process is in successful operation in several major production plants in Europe, Australasia, Central America and the Middle East. Throughputs vary but typically range from 50-500 kg per hour. In Germany, a 1000mm diameter TORBED reactor processes some 1000 tonnes per year of low fat snack products to supply just one regional supermarket chain.Traditionally spices have been pasteurised by steam or radiation. The former technique has limitations in terms of product quality and ultimate levels of pasteurisation. It has been found by extensive trials on a range of spices that much lower residual contamination can be achieved using the TORBED reactor with hot air as the process medium.

The TORBED process has shown itself to have unique capabilities in these applications in producing higher quality, more consistent product at a low energy consumption with low residual contamination levels.The process can rapidly be changed for different products and characteristics. The installation is quiet and compact. Pilot trials have been successfully carried out and full scale production plant is in operation processing 300 - 400 kg/h of spices.

Many other precision roasting, drying and bloating processes are in commercial use in most major continents of the world.